Thermal Break products

Armatherm™ structural thermal break materials provide a combination of low thermal conductivity and high compressive strength. They have been specifically designed and tested to transfer load and prevent thermal bridging. Armatherm™ has been proven through three dimensional modeling to reduce heat loss in wall assemblies, transitions and structural connections throughout the building envelope

Armatherm™ Z Girt

Armatherm Z Girt is a nonconductive cladding support system, strong enough to hold most cladding and insulation details.

Armatherm™ FRR

Armatherm FRR is an extremely strong and durable thermal break material suitable for supporting heavy loads while cutting conductive heat loss.

Armatherm™ 500

Armatherm 500 is a high strength, polyurethane material manufactured in several densities to support a wide range of building loads.

Armatherm™ FRR thermal break solution

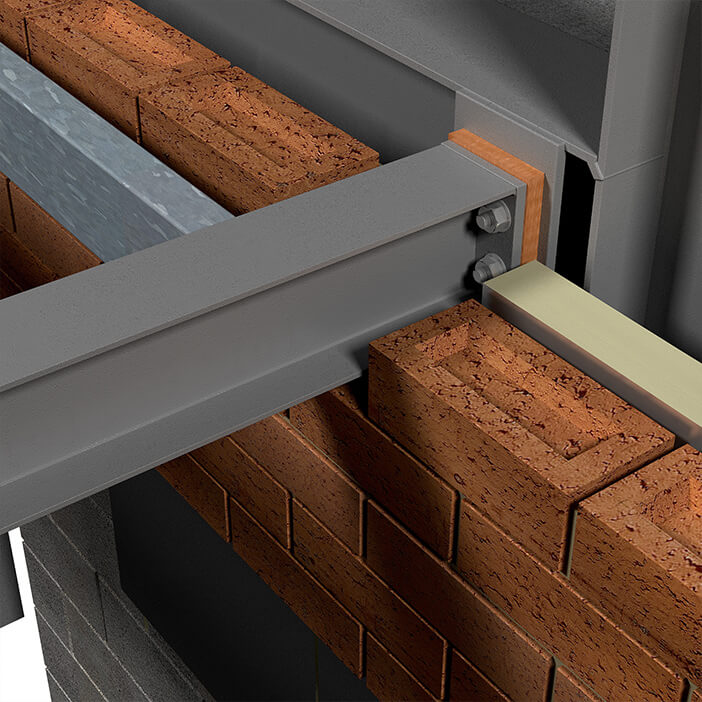

Armatherm™ FRR is a powerful thermal break material solution made of a reinforced, thermoset resin which provides low thermal conductivity properties and high compressive strength. The elements that make up the thermoset resin mean it boasts a range of advantages and benefits, including limited combustibility and reduced creep under max load- making it the ideal choice for use in structural thermal break connections to improve energy efficiency.

Reducing heat flow within a building’s thermal envelope massively reduces the energy consumption of the structure, as well as potentially dangerous and damaging condensation issues which can lead to mold, rust and corrosion.. Thermal bridging through steel and concrete framing can have a significant impact on energy performance of a building, so incorporating thermal breaks to minimize the transfer of energy and is an integral step in working towards more efficient buildings.

The FRR material from Armatherm™can be used in a variety of applications. It’s available in different forms to suit your project including sheets, washers and bushings with impressive specifications for thermal isolation. Armatherm™ FRR sheets can be bonded together to satisfy U value and thickness specification requirements if your project requires more than the sheets allow, but with thicknesses including 1/2”, 3/4”, 1,” & 2” 1/16″, 1/8″, 1/4″, 3/8″, 5/8″, 7/8″, the correct thickness needed for an application can easily be specified or created.

Armatherm FRR is as versatile as it is strong. It can be shipped in 4’X4’ sheets but more commonly is precision cut to size and drilled in the factory to meet your specifications. FRR comes in several standard thicknesses or can be permanently built up and bonded together by us to make custom thicknesses – within a 1/16 of an inch tolerance. Armatherm washers and bushings can be added to the connection to further improve the connection’s performance by up to 10%.

Alongside the importance of thermal breaks sheets being incorporated within steel and concrete framing, a thermal break should also be specified for the front side of the bolt head between the steel washer and face of the exterior steel. Including thermal breaks at these points prevents a thermal bridge through the bolt which would otherwise provide a path for heat flow through the thermal break assembly, resulting in a loss of energy from inside the building. Armatherm™ washers and bushings are essential in blocking this path and reducing the potential for condensation within the building envelope.

Armatherm™ 500 thermal break solution

Armatherm ™500 is a high strength thermal break, made from a revolutionary polyurethane material manufactured in several densities to support a vast range of loading conditions within a building’s structure. It harbors a closed cell structure which does not absorb water and has very limited creep under load. The 500 Series offers several R-value choices to reach your efficiency goals. This helps significantly reduce energy lost from thermal bridging within building envelope connections, reducing heat flow, energy consumption and potential condensation issues which can cause monumental damage in a building.

Armatherm 500 is available in 4’X8’ sheets or can be cut and drilled to your specifications in our factory, and will be shipped ready to install at the job site. Standard thicknesses are in stock or we can manufacture about any thickness you need.

Available in sheet form, Armatherm ™500 can easily be layered together to achieve the desired U value and thickness specifications. (START AGAIN HERE) Its versatility means it can be used anywhere that features a penetration or transition exits through a building envelope where a thermal bridge occurs, including parapets, slab/floor edge, roof penetrations, custom window sills, concrete balconies and more. This innovative material is user friendly and can be cut and drilled on site easily if required.

Although it is often used to prevent thermal bridging to keep warm temperatures within a building, it can also be essential in cold storage facilities to prevent the subgrade from freezing. It can sit directly under the column base to prevent any transfer of temperature into the ground.

Armatherm™ Z-girt thermal break solution

The Armatherm™Z girt is a non-metallic thermal break, ideal for use within exterior wall projects, on new or existing wood or steel stud wall assemblies, or with CMU or concrete walls. The Z-girts were developed to reduce heat loss in the building envelope and overall increase the effective R-value of the total wall assembly. Z-Girts provide a secure way to retain continuous exterior insulation, while providing a secure surface to attach most cladding and siding materials. Made from fiber-reinforced plastic, tests have shown that incorporating the Z-girts can result in several improvements within the thermal efficiency of the wall design, reducing the heat flow and energy transfers.

Featuring a traditional Z girt shape, the structural material is used for holding insulation and mounting cladding or sliding but is much more efficient than its steel counterparts. The non-conductive Armatherm™ Z-girt offers as much as a 75% improvement over traditional steel Z-girts which is an invaluable statistic for architects looking for energy efficient solutions.

Wall assemblies that feature Armatherm™ thermal break products can reach up to 98% efficiency, as well as having less potential to develop condensation issues that can be extremely damaging to a building and the health of those inside. Cladding attachments are significantly improved when a combination of thermal break products are specified, with Z-girt, clips and shims all used to achieve maximum efficiency across the board.

Thermal break resources

We have a number of valuable online resources that you can take advantage of on our website, including test reports, extensive literature libraries, design assistance and product profile videos to help you understand the importance of thermal break products, the key features of our materials and the applications in which they can be used. If you require CAD drawings for your project, these can be accessed via the Armatherm™website and downloaded to be easily incorporated into your project plans.

We also have an easy-to-follow online webinar which is ideal for architects looking to earn credits, with the course providing an overview and introduction to thermal bridging, discussing how and why it occurs, as well as how it can be prevented. By completing the webinar, you can gain one AIA HSW learning credit while learning more about thermal break solutions. It provides you with essential knowledge surrounding energy savings and information to help understand how to incorporate thermal breaks into your next project effectively to control thermal bridging issues. It also showcases and compares the difference between building details with and without thermal break solutions to highlight the importance of determining accurate values of thermal transmittance within a project.

For help with your construction project, you can get in touch with our team of experts who are on hand to help with any queries you may have regarding thermal bridging and how to prevent it. You can also keep up to date with all things Armatherm™on the news section of our website where we upload case studies, latest projects and the latest industry news and updates.

Thermal Break Projects

We’re proud to have provided Armatherm™ materials for a number of prestigious projects including Denver International Airport and the University of Illinois’ Townsend Hall to help them meet efficiency regulations. If you’d like to hear from some of the companies we’ve worked with, check out our testimonials. We have glowing reviews from our customers and they’d be more than happy to put your mind at ease regarding any reservations you may have regarding working with us on your construction projects. We also have a number of case studies which showcase how our products and materials have assisted in creating efficient structures for customers.

About Armatherm™

Armatherm™’s goal is to provide architects, structural engineers and building design professionals with effective solutions to prevent thermal bridging. We’re one of the leading suppliers of structural thermal break materials in North America for the construction industry and we’re dedicated to improving the future of the construction industry. Our goal is to provide architects, specifiers and structural engineers with the essential knowledge and access to the products to achieve maximum efficiency. Thermal bridging has been recognised as a significant factor in building envelope heat loss. Armatherm™ thermal break materials have low thermal conductivity and high strength and have been designed and tested to reduce thermal bridging. Armatherm structural insulation can provide solutions to difficult thermal bridging challenges that were beyond traditional building practices. Armatherm™ thermal bridging solutions can provide continuous insulation where a penetration or transition exists in a building’s thermal envelope creating a thermal bridge. An innovative solution, the Armatherm™ structural thermal break materials minimize heat loss at balcony, canopy, parapet, masonry shelf angles and cladding connections. Thermal insulation materials must be considered by specifiers, architects and structural engineers to ensure projects are as energy efficient as possible, saving money in energy costs and protecting the future of constructions.

Need help?

Contact us today to find out more or request a quote.

UK

UK USA

USA Canada

Canada Australia

Australia New Zealand

New Zealand Germany

Germany UAE

UAE Ireland

Ireland Sweden

Sweden Denmark

Denmark Norway

Norway