What is cold bridging?

Cold bridging is a break in the insulation, or spots where there is less insulation all together. A key issue with thermal or cold bridging is, at points where the insulation is penetrated by an element with higher thermal conductivity, energy will transfer through these materials. To put it simply, conductive materials form a bridge between the inside and outside of the building. Where the building is situated in a colder climate, this can result in additional heat loss at these points.

Cold Bridging Solutions

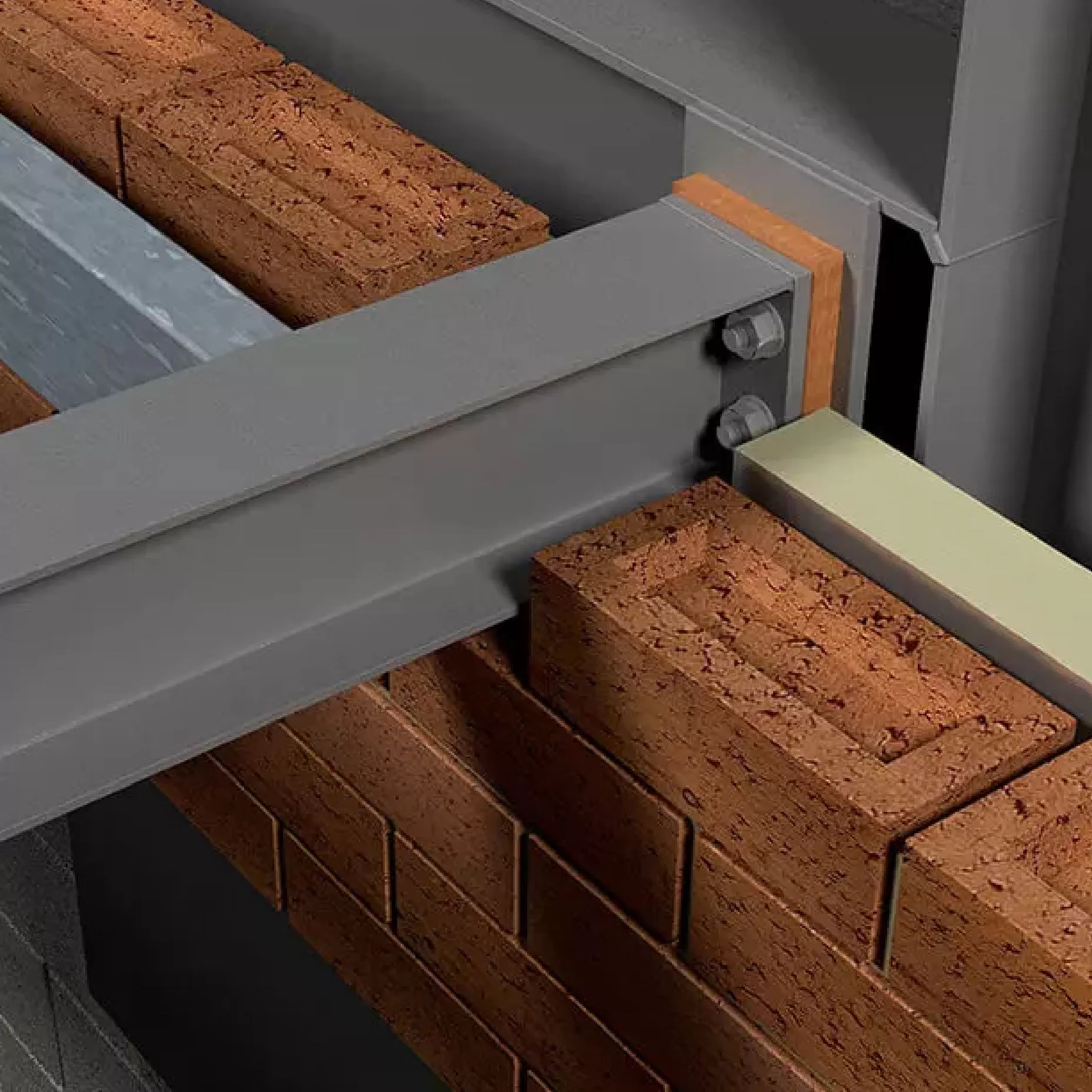

The ArmaGirt™ Z Girt is a nonconductive cladding support system, strong enough to hold most insulation cladding additions. This thermally broken cladding support material prevents excessive potential condensation. Also, heat flow problems which could arise without the inclusion of a thermal break product. Modeling results show that incorporating Armagirt Z Girt within a cladding project results in several improvements within the thermal efficiency of the wall design, dramatically reducing the heat flow. The innovative design means that the attachments can significantly improve the wall assembly’s thermal performance. For the ultimate solution when it comes to cladding, a combination of Z-girt, clip and shims can deliver the lowest levels of thermal conductivity and high mechanical properties that transfer load while reducing heat loss.

A strong and durable thermal break option, Armatherm™ FRR is suitable for supporting heavier loads while minimising conductive heat loss through the insulation layers. This structural thermal break provides an innovative combination of low thermal conductivity and high compressive strength. It has been specified in hundreds of structural steel framing connections, transferring load in moment and shear conditions. Made from reinforced, thermoset resin, this material is fire resistant and has the ability to support up to 43,000 psi and has an R value of 0.9 per inch. It’s ideal for structural steel and façade thermal break applications.

Armatherm™ 500 is a high strength, polyurethane material, available in a number of different densities to support a wide range of building loads. Incorporating Armatherm 500 thermal breaks within a project significantly reduces energy consumption as well as potential condensation issues. The material is high strength and will reduce energy lost from the building envelope, in a variety of connections. It is made from a high strength, thermoset polyurethane, and manufactured in a variety of densities to provide unrivaled energy saving properties to a number of projects. Armatherm™ 500 can transfer a wide range of structural loads with a range from 20 psi – 4000 psi. Compared to aerated concrete and wood blocking, Armatherm™ 500 has R values as high as 3.8 per inch which is highly superior.

Learn more about cold bridging

If you’d like to learn more about cold bridging, we have a dedicated team who work hard to ensure support is there for architects and their professional development. Armatherm™’s AIA seminar, “Build Better with Thermal Breaks” gives architects an insight to gain a better understanding of the invaluable properties and savings thermal breaks can offer, as well as how to apply them effectively in your next project to prevent thermal bridging issues. The course has one AIAA LU HSW credit available, you can sign up via the Armatherm website, or by visiting the Hanley Wood University to learn about thermal bridging on your own schedule.