Armatherm application

Product

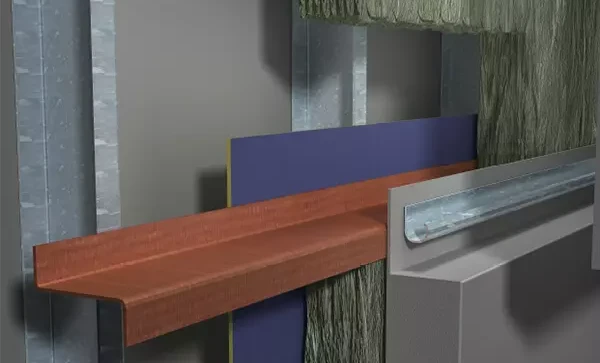

CLADDING THERMAL BRIDGING SOLUTIONS

Continuous insulation is almost always compromised by metallic structural connections such as clips and girts which create thermal bridging when connected to steel stud framing. A thermal bridge is an area of building which experiences higher heat transfer than the surrounding materials. These connections in conjunction with the steel studs have a significant impact on the U value of wall assemblies.

Insulation effectiveness can be reduced by as much as 50% due to these heat flow paths. Armatherm™’s cladding solutions can effectively prevent excessive heat losses. ArmaGirt improves the U value of cladding and wall panel assemblies by eliminating the use of highly conductive metal girts and aluminum brackets creating wall assemblies that are up to 98% efficient.

ARMAGIRT™Benefits

- Approved to NFPA 285 standards

- Works with a wide range of cladding systems

- Direct replacement to conductive steel girts

- Can run vertically and horizontally

- Matches standard installation techniques

- Excellent resistance to UV

Cladding Thermal Break

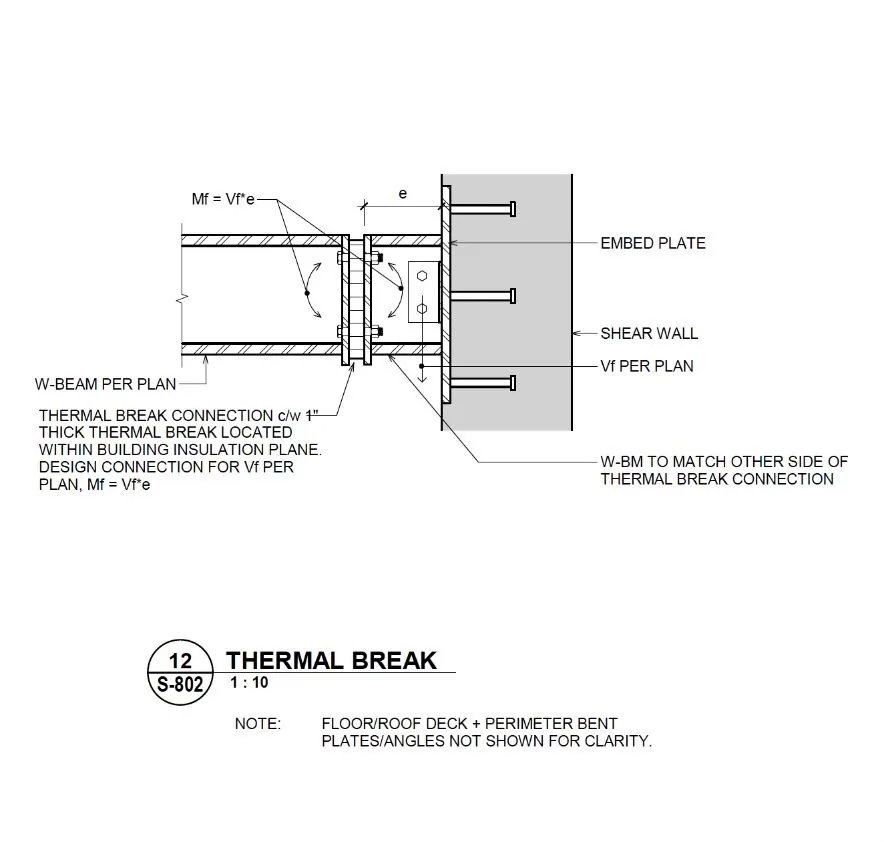

Armatherm cladding attachments significantly reduce thermal bridging and improve wall assembly thermal performance. ArmaGirt, clip and structural thermal break materials provide a combination of low thermal conductivity and high compressive strength transferring load and reducing heat loss.

The Armatherm™’s cladding material is made of a reinforced, thermoset resin that is fire resistant and exhibits very limited creep under load, making it the ideal material for use in structural and façade thermal break connections. The thermal images below demonstrate the efficiency of the connections in retaining insulated heat.

Downloads

Request a Quote

If you require a quotation and know the following product information, complete through form below.

ArmaGirt Z Girt is specifically designed to improve the thermal efficiency of wall designs, reducing heat flow. The insulation efficiencies of the wall assemblies improve considerably, with the highest levels rising to 98% efficiency. These support connections prevent heat loss and subsequent condensation issues associated with thermal bridging.

Not only this, using ArmaGirt Z Girt with wall assemblies conforms to the continuous insulation requirement of ASHRAE 90.1, as well as the effective R value requirements of the Canadian NECB energy code. Therefore, your buildings will remain inline with government conditions.

ArmaGirt is also advantageous to structures as it is reduced in thickness, resulting in lower costs of insulation. These cladding wall assemblies can also meet the R value requirements of all geographical zones for both ASHRAE 2013 and NECB 2011 energy codes. Armatherm TM Z Girt, clip and thermal break shims provide a combination of low thermal conductivity and high mechanical properties that transfer load and reduce heat loss.

Contact our dedicated team to gain further insight into our innovative products. We work hard to ensure support is available for architects’ professional development, alongside providing the required products for their needs. Our courses and learning resources are also available online for you to learn more. Furthermore, Armatherm™’s webinar, “Thermal Bridging Solutions: Improving Building Envelope Performance” gives architects an insight to gain a better understanding of the invaluable properties and savings thermal breaks can offer, as well as how to apply them effectively in your next project to prevent thermal bridging issues.

Contact our expert customer service team to answer questions about your next project. Armatherm offers several different thermal break products to help you address the challenges of designing and building efficiently. We offer seminars online and in person if available where we can get you up to date on the latest developments in thermal break products. We work hard to provide the resources that will support the design and building industry. Visit our website for more information.

Ensure that you get in touch with our expert team to learn more about the ground-breaking products we offer. We work hard to ensure support is available for architects’ professional development, alongside providing the required products for their needs. Our courses and learning resources are also available online for you to learn more.

Armatherm™’s AIA seminar, “Build Better with Thermal Breaks” gives architects an insight to gain a better understanding of the invaluable properties and savings thermal breaks can offer, as well as how to apply them effectively in your next project to prevent thermal bridging issues