What’s the Difference Between a Thermal Bridge and a Thermal Break?

When striving to create more efficient buildings, there’s so much terminology to understand, and while thermal breaks and thermal bridges have very opposite meanings, they are frequently confused with one another.

What Is a Thermal Bridge?

Starting with thermal bridges, these are connections within a construction that feature higher thermal conductivity than any of the other materials around it. It creates a path (or bridge) for heat to use to enter or leave the building envelope, resulting in lower thermal resistance and an overall inefficient and less economical building.

At these connections, the heat is transferred via conduction, and the rate at which it moves is determined by temperature difference at the end of each thermal bridge. It can also be measured by looking at the thermal conductivity of the material before it is included within a build.

With thermal bridges allowing heat to enter or escape a building, this can create a whole host of issues. From not meeting efficiency regulations to causing mold from condensation, along with higher energy bills and reduced occupant comfort, thermal bridges need to be properly considered by architects and project managers to understand the detrimental issues they can cause. Once they’re better understood, they can be properly isolated.

What Is a Thermal Break and How Does It Work?

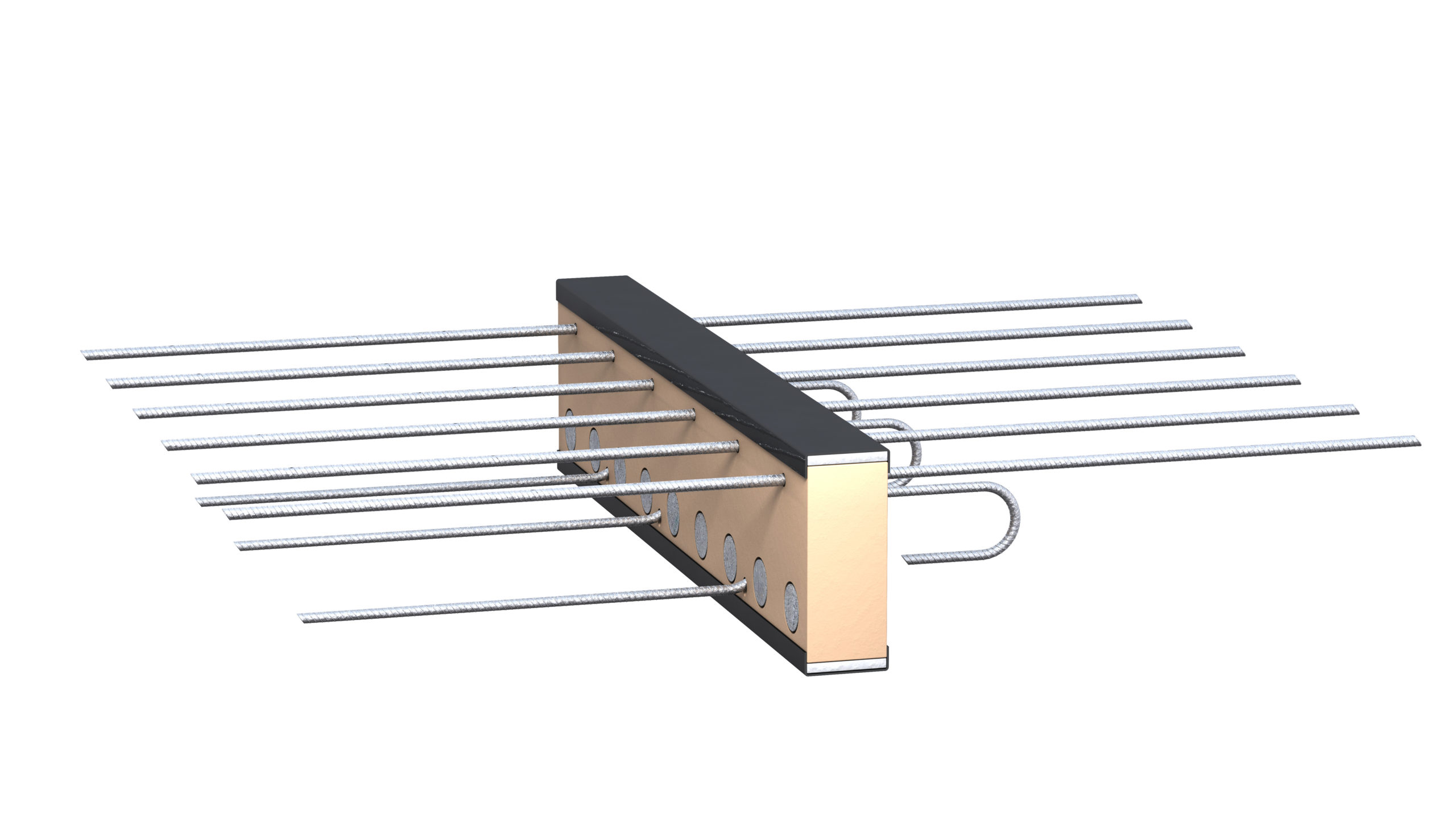

Thermal breaks are the solution to a thermal bridge. Think of it as breaking the bridge, putting a material in the way of the heat transfer to minimize the amount of energy that can pass through.

An efficient thermal break which prevents and reduces thermal bridging is known as a continuous layer of insulation. Continuous insulation is not interrupted by materials with high thermal conductivity, it slows the movement of heat through any of the building elements and helps to achieve better energy efficiency statistics.

Where Do Thermal Bridges Commonly Occur in Construction?

New regulations are coming into play across the globe to ensure a brighter future for the construction industry. More efforts need to be made to create efficient structures today so the future of these buildings can be protected.

Bridges can occur within a number of connections including column base, masonry shelf angle, balcony, canopy, roof penetrations and foundation wall connections.

Armatherm™ can help with our innovative thermal break solutions for each of these points. For more information, please get in touch with our team of experts.