Applications

Armatherm™ 500 Structural Thermal Break Material

(Thermal Insulation Material – TIM)

Reducing heat flow within a building’s thermal envelope reduces energy consumption as well as potential condensation issues.

Armatherm™ 500 thermal break material (TIM) significantly reduces energy lost from thermal bridging in building envelope connections. Armatherm™ 500 structural thermal break material is a high density, thermoset polyurethane manufactured in several densities. Armatherm™ 500, made in the USA, is able to transfer a wide range of structural loads with a range from 20 psi – 2,150 psi. Armatherm™ 500 has R values as high as 3.8 per inch which is superior to the properties of aerated concrete and wood blocking. The Armatherm™ 500 thermal insulation blocks do not absorb water due to its closed cell structure, and has very limited creep under load. This helps reduce energy lost via thermal bridging pathways within building envelope connections, reducing heat flow, energy consumption and potentially dangerous condensation issues.

The standard thicknesses Armatherm™ 500 is available in are 2”, 1” and 1/2”, but the high density, polyurethane material sheets can easily customised or layered to achieve the desired U value and thickness specifications. It is very versatile and can be used anywhere that features a penetration or transition exit through a building envelope where a thermal bridge occurs and can be cut and drilled on site easily, if required. The most common specifications include Armatherm™500 150 and Armatherm ™500 200. Although it is often specified to prevent thermal bridging in buildings to reduce heat loss, Armatherm™500 is ideal for cold storage facilities to prevent the subgrade from freezing. It can sit directly under the column base to help prevent the transfer of cold temperatures into the ground, making it the perfect solution for frozen food storage.

ARMATHERM™500 Benefits

- High/medium compressive strength connections

- Lowest thermal conductivity available

- Lasts the life of the building

- Excellent resistance to UV and Moisture absorption

- Reduces condensation and mould

- Manufactured to design specification

Armatherm resources

Downloads

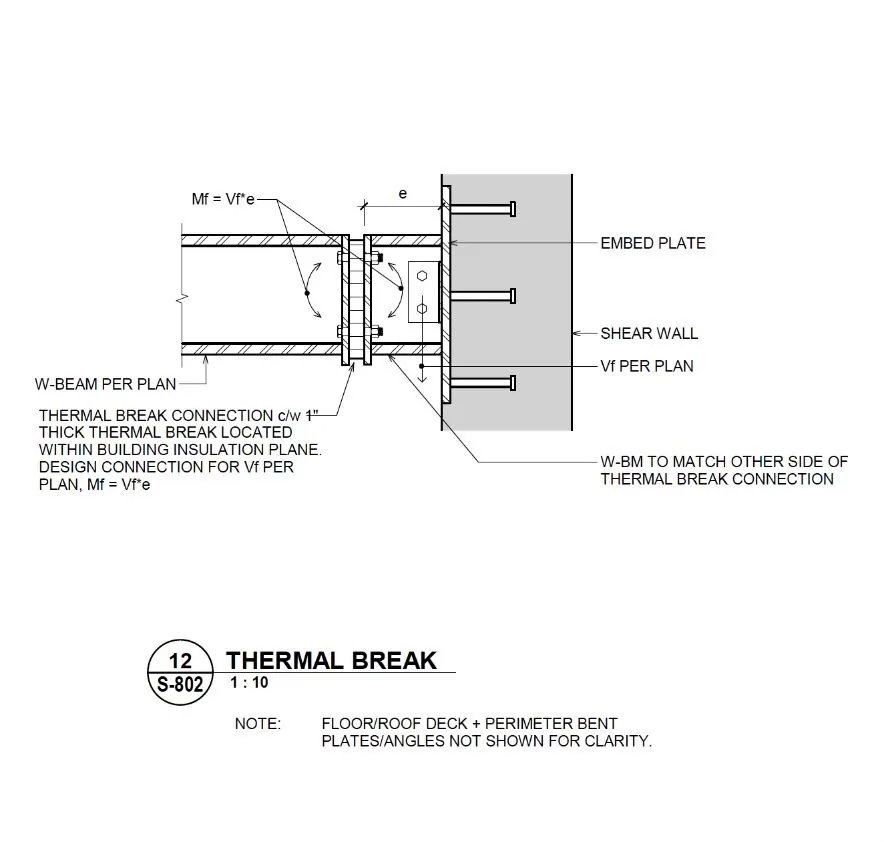

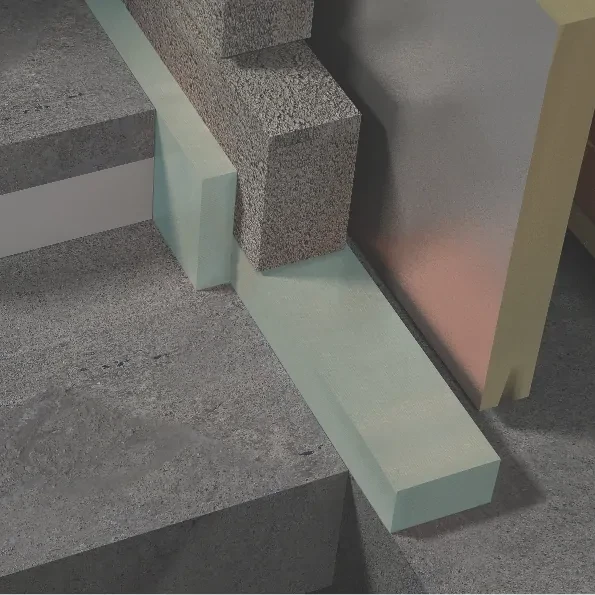

Thermal bridging is necessary in locations such as roof to wall and parapets as they require structural framing for support. By including thermal break materials under the parapet connecting the facade and roof insulation, the R value can be improved by as much as 30%. Within the building envelope, a thermal break can also be installed at roof penetration points where structural elements are supported.

In a traditional structure, columns extend throughout the building envelope and slab insulation are positioned at their base. Cold bridges can be prevented with the use of a thermal break. Armatherm™ 500 has a limited creep under load as well as high density, making it the best solution for load supporting thermal break requirements.

Further areas with the potential to feature thermal bridges are the foundations of a building and the connection from slab on grade to a foundation wall. Energy loss can be reduced dramatically with the addition of an Armatherm™ 500 series thermal insulation block which support exceptionally high loads of up to 300N/mm2.

Thermal Bridging Resources

For a number of helpful online resources to take advantage of, including test reports, design assistance, literature libraries and product profile videos to help you achieve a better understanding of thermal break products, key features of the materials and the applications they’re best suited to. You can also access CAD drawings on our website, they’re available to download and can easily be incorporated into your project plans.

For architects looking to earn valuable credits, we also have an easy-to-follow webinar that gives an overview and introduction into thermal bridging, the issues it causes, how and why it occurs, as well as the best methods of prevention. It provides essential knowledge surrounding energy savings within the construction industry, and how to effectively incorporate thermal breaks into your project to minimize thermal bridging issues.

Projects & Testimonials

We’ve provided materials for a number of prestigious projects. If you’d like to hear from any of the companies we’ve worked with, check out the testimonials on our website. We have glowing reviews and our team would be more than happy to put your mind at ease regarding any reservations you may have regarding working with us on your construction projects. We also have a number of case studies to showcase how our products have assisted in creating efficient structures for customers. Thanks to Armatherm™ 500 US buildings can be made considerably more efficient.

Consultancy & Support

Safe, durable and efficient Armatherm™ thermal bridging solutions can help minimize energy loss and significantly improve envelope performance with a vast range of thermal break products. If you need help with your construction project to meet new building regulations, you can get in touch with our expert team who are on hand to answer any questions you may have regarding thermal bridging and how to prevent it with innovative products. You can also visit our website and keep up to date with all things Armatherm™, along with case studies and the latest industry news and developments. We can make sure the Armatherm™500 price is right for your project.

Request a Quote

If you require a quotation and know the following product information, complete through form below.