Armatherm™ Thermal Break Washers & Screws

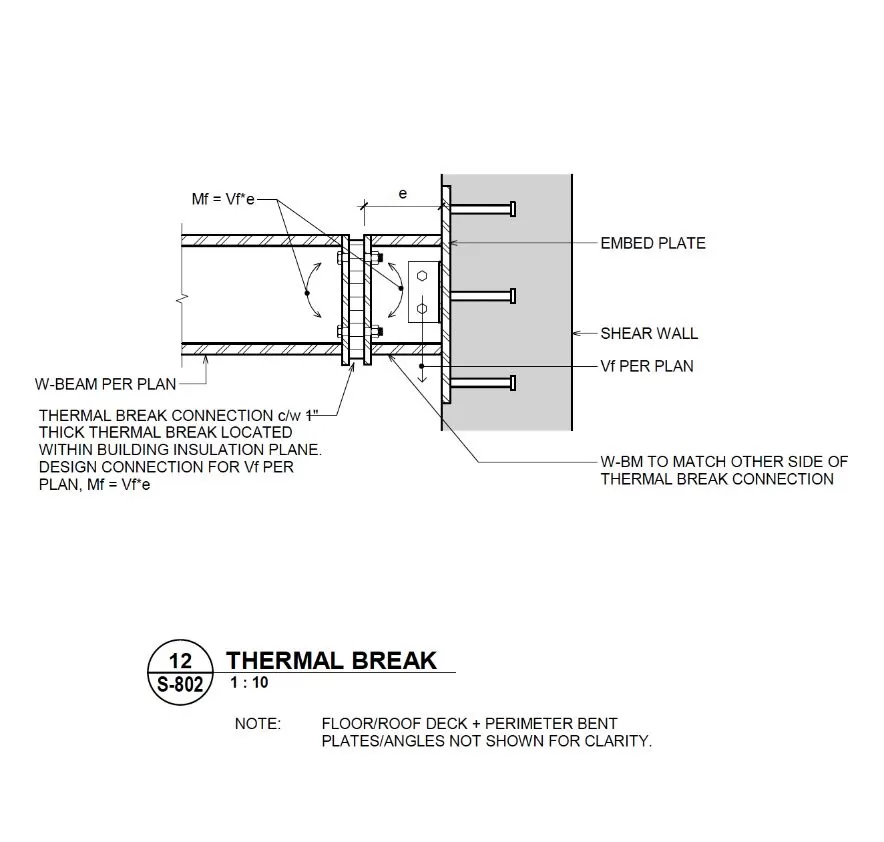

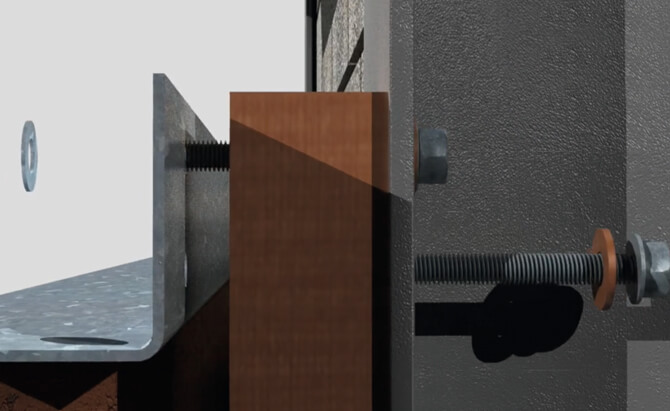

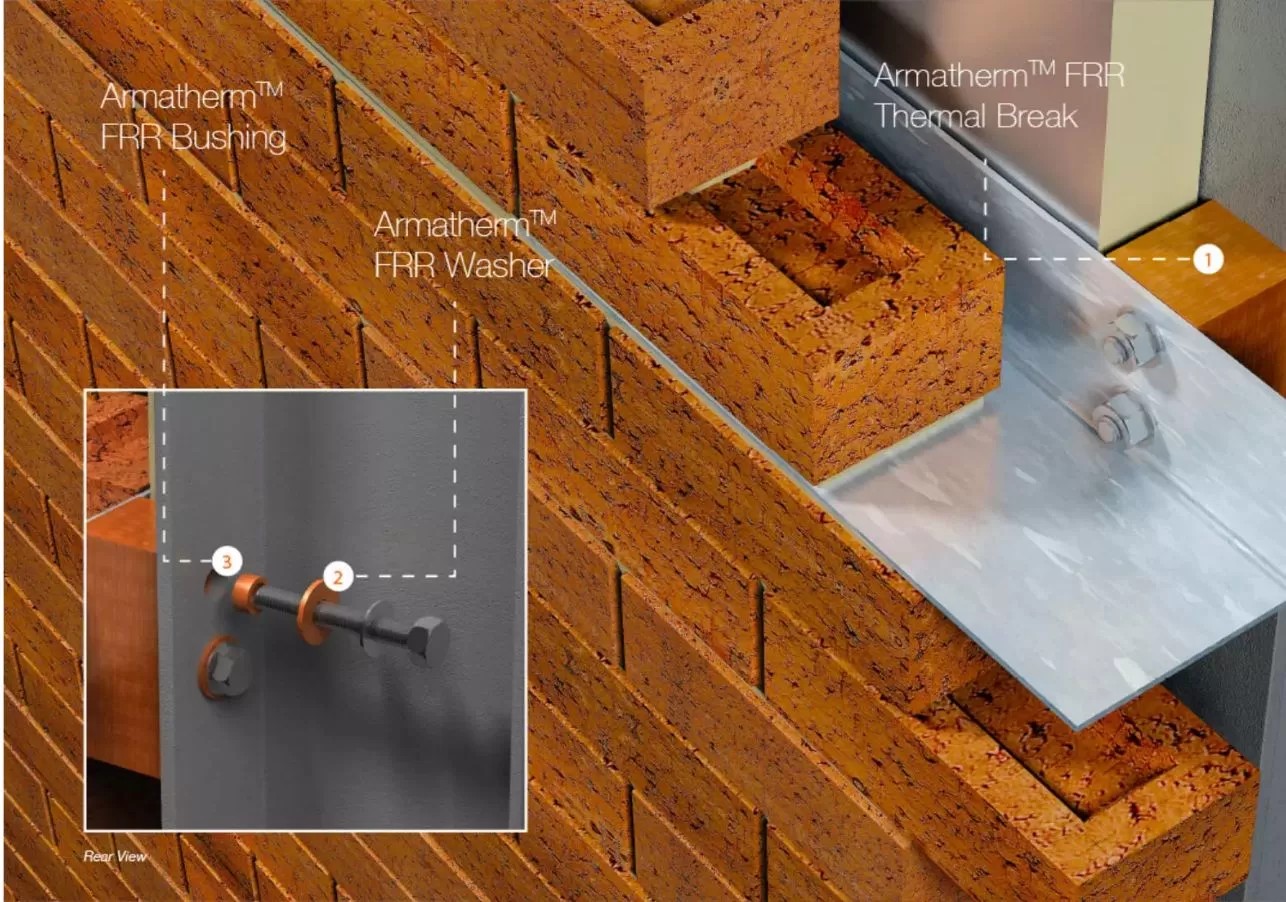

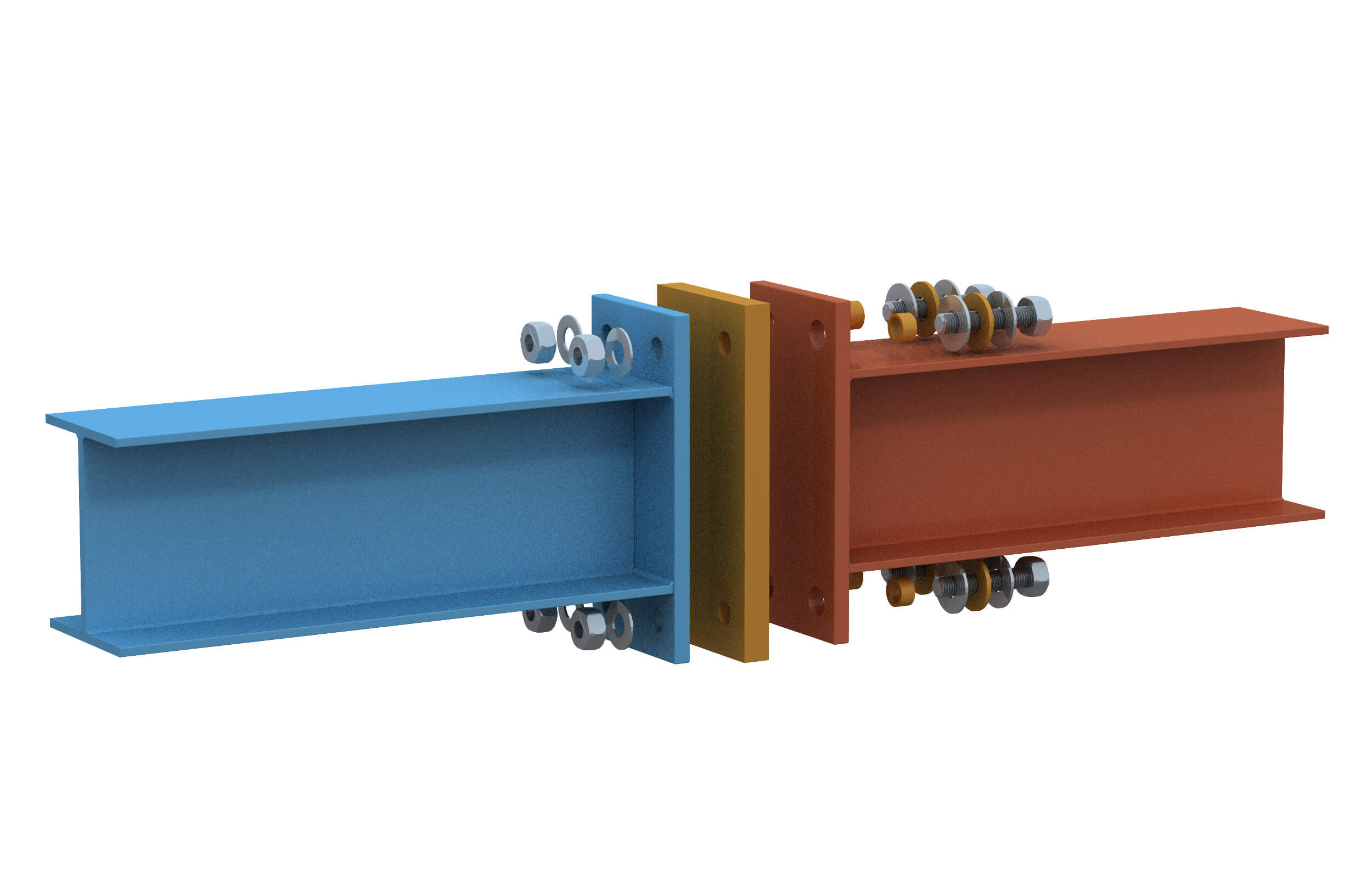

Installing thermal breaks is essential to ensure maximum efficiency, but another element to consider is the fixings used to attach these. Even if a connection is totally thermally isolated thanks to a Z Girt for example, the attachments can result in a less efficient connection, allowing a path to develop via the screws. Incorporating Armatherm™ washer creates thermal break screws, meaning the connection is as thermally isolated as possible, with no opportunity for bridges to occur. A thermal break should be provided at the front side of the bolt head between the steel washer and face of the exterior steel, reducing any potential energy loss.

The Armatherm™ thermal break washers and bushings can be used on the warm face of the structure, and including a thermal break at the bolt connection will reduce heat loss an additional 4% per bolt, depending on the wall assembly connection. Without these thermal break solutions, condensation can occur on the bolt heads which can develop into damp and mold issues. To prevent this, a polyurethane nut / bolt cap can be supplied and added to effectively isolate the cold surface from the warm internal environment of the inside of the building. Polyurethane is an insulative material, thanks to its chemical composition energy cannot flow through it, making it ideal for thermal isolation. It can place a direct block between the warmer internal temperatures and the colder external temperatures traveling via conductive penetrations to the building envelope, such as steel bolts and fixings.

Improve Efficiency by up to 70%

As America works towards reducing carbon emissions by 2030, it’s imperative to identify where improvements can be made and use materials that will last the lifetime of the building. Armatherm™ is continuously improving, and is always developing new products to meet the needs of energy efficient buildings. Specifying thermal breaks can improve the efficiency of a building by as much as 70%, resulting in a more efficient project with lower operating costs and prevention against cold spots where condensation and mold can occur.

Our dedicated team is on hand to help with any queries or reservations you may have regarding thermal breaks. We can help you at the very initial stages of your project to specify the best products for the job, that will assist a construction in meeting essential energy saving regulations. We are dedicated to providing the industry with effective solutions to protect the future of construction.

OurAccreditations

Request a Quote

If you require a quotation and know the following product information, complete through form below.