Applications

Armatherm™ FRR Structural Thermal Break Material

(Thermal Insulation Material – TIM)

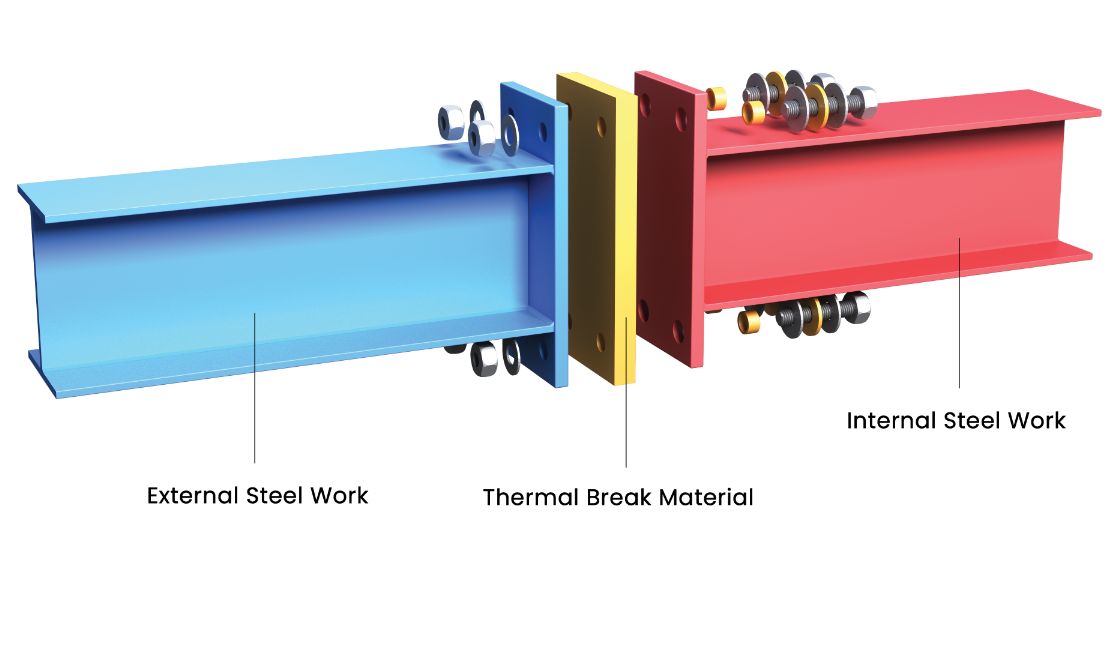

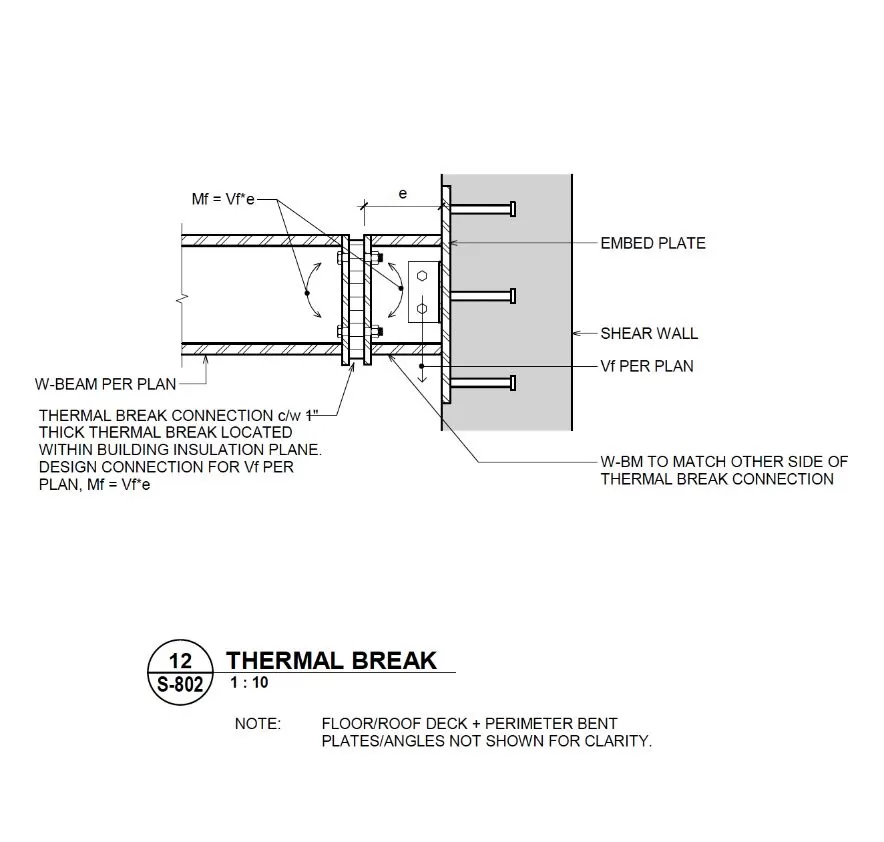

Hundreds of structural steel framing connections transferring load in moment and shear circumstances have used Armatherm™ FRR structural thermal break material. This combines low heat conductivity and strong compressive strength.

High loads can be supported by Armatherm™ FRR thermal break material, which also has excellent mechanical qualities. The material is constructed of a reinforced, thermoset resin that resists fire, making it the perfect choice for use in thermal break connections for structural steel and façades.

Thermal Bridges, balcony isolators, structural thermal breaks, cantilever steelwork thermal bridging, cold bridge isolation, thermal partitions, steelwork thermal break, thermal bridging, cold bridging pads, and cold bridging solutions are all versions of Armatherm™ Thermal Break Pads. To avoid thermal bridging, all of these techniques make use of Thermal Insulation Material (TIM).

ARMATHERM™FRR Benefits

- Ultra high compressive strength connections

- Recommended for moment and slip critical connections

- Lasts the life of the building

- Excellent resistance to UV and Moisture absorption

- Reduces condensation and mould

- Outstanding resistance to long term creep

- Manufactured to design specification

Armatherm resources

Downloads

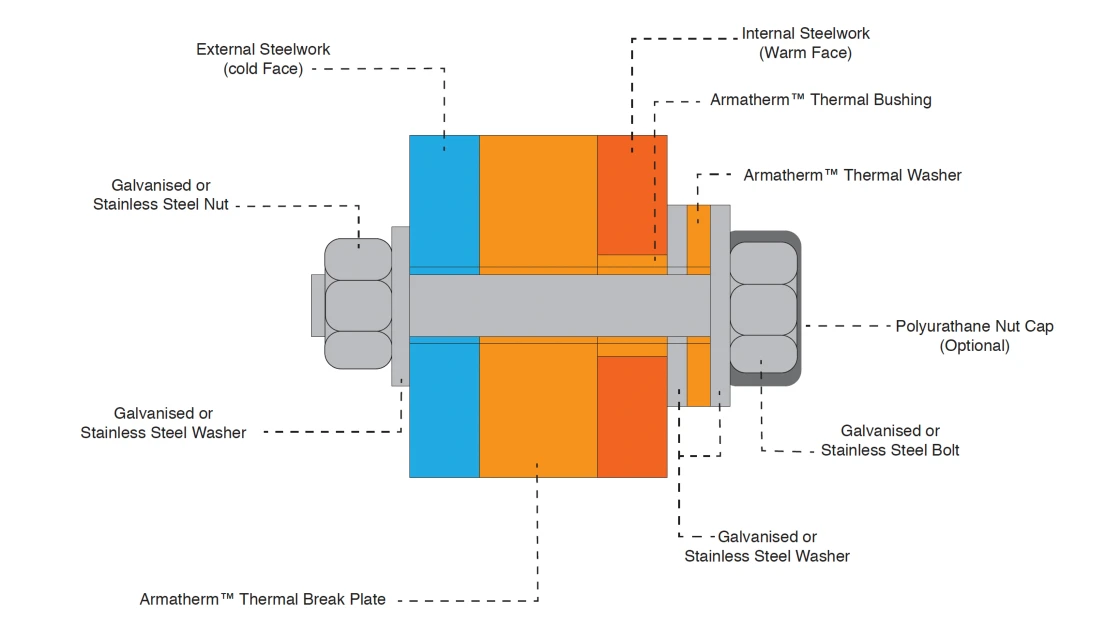

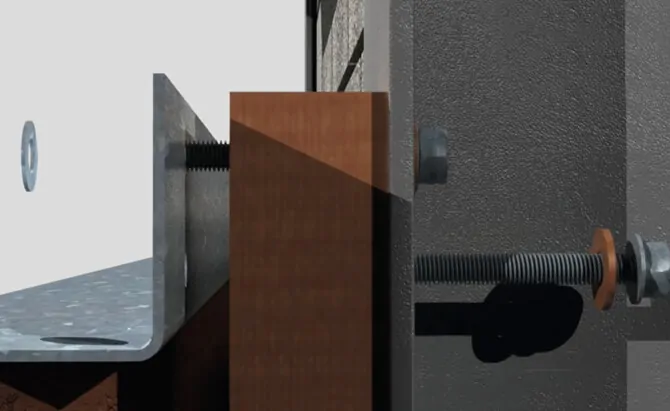

Armatherm™ Thermal Washers and Bushings

There is a minor thermal transfer along the connecting bolt with a bolt through the insulation pad.

On the warm face of the structure, ArmathermTM bushings and washers can be employed to further decrease heat loss. Depending on the design of the wall assembly, a thermal break at the bolt connection will reduce heat loss by an additional 4% per bolt.

A polyurethane nut cap can be provided in extreme applications (such as indoor swimming pools) to adequately screen this chilly surface from the interior environment and prevent condensation on the bolt head.

Request a Quote

If you require a quotation and know the following product information, complete through form below.

Armatherm™ FRR thermal break material can support high loads of up to 40,000 psi and has an R value of 0.9 per inch, as well as great mechanical properties.

As used within a number of prestigious, high-profile projects across the world, the Armatherm™ product range includes the innovative FRR material which harbors inert and water resistant qualities. This makes it ideal for a number of applications and locations, including cladding fixings, foundation to wall transitions, column base and roof penetrations.

With more legislation changes coming into play each year to protect the future of the construction industry, Armatherm™ can be used in renovation projects to rectify a number of poorly isolated connections within existing buildings, as well as structures under construction to make them as efficient as possible. To achieve this and work towards making any building as efficient as possible, these solutions need to be considered within the earliest stages of a construction project, which is why it’s imperative for architects to understand the importance of these products and how they can help a structure meet certain efficiency criteria.

The FRR product specifically, is a structurally sound high performance thermal break material which delivers thermal insulation between interior and exterior steelwork, and / or concrete, to prevent thermal bridging. It can help work towards improving building envelope performance, dramatically reducing heat loss and preventing surface condensation from forming inside the building that can be caused by cold transfer meeting warm air. Structural thermal break concrete connections are at high risk of making a building inefficient so it’s imperative that solutions are considered.

With its durable, long-lasting and cost-effective properties, along with lower repair and maintenance costs, concrete is often widely specified within the building industry. Although concrete naturally provides a high level of thermal mass, which enables it to absorb, store and release heat to regulate a building’s temperature, a simple penetration through the material or the presence of another can cause a thermal bridge. Should this occur, it will hugely impact the energy efficiency of a building as well as increasing its running costs, resulting in an inefficient and uneconomical structure. When working with such materials, structural steel thermal breaks must be at the forefront of plans to ensure all the framework, foundations and building envelope is as efficient as possible.

When using structural thermal break pads in a parapet roof location, the U value of the roof assembly will be improved, and the potential chances of condensation problems occurring will be prevented at the structural connection. The FRR and 500 series thermal break materials can transfer the loading conditions in these applications while simultaneously reducing heat flow significantly, creating continuous insulation. The efficiency of these locations can be improved by as much as 80% which is invaluable in light of legislation updates and changes.

With more than 40 years’ experience, the Armatherm™ team can advise which Armatherm™ structural thermal break products will work best for your projects, and are more than happy to answer any questions you may have. Specified for a number of structural thermal break US projects, including thermal breaks in structural steel the solutions are proven to be some of the best in the industry.

Get in touch today to find out how we can help and specify efficient solutions for your building.