Applications

ArmaGirt™

Thermal Efficiency & Code Compliance

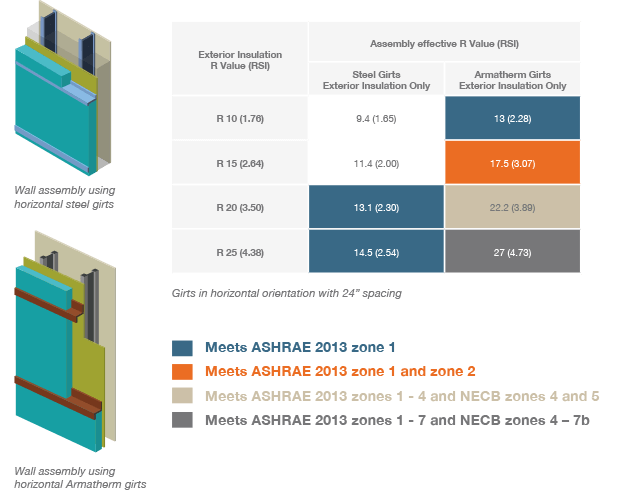

Armatherm™ cladding attachments help limit heat loss and prevent condensation problems typically caused by thermal bridging. By isolating the warm side of the wall from the cooler exterior, ArmaGirt™ Z-Girts allow wall assemblies to achieve continuous insulation values required by ASHRAE 90.1 and the Canadian NECB energy standards.

Specifying Armatherm™ thermal breaks can raise wall assembly efficiency by as much as 98%. The Armatherm™ range including Z-Girts, clips and thermally broken shims delivers low thermal conductivity combined with high structural strength, effectively transferring loads while reducing energy transfer.

ARMAGIRT™

Benefits

- Approved to NFPA 285 test standards

- Works with a wide range of cladding systems

- Direct replacement to conductive steel girts

- Can run vertically and horizontally

- Matches standard installation techniques

- Excellent resistance to UV

Improve Wall Assembly Efficiency

How do we optimize cladding attachment details and design wall assemblies that maximize insulation performance, cut down on heat loss and comply with energy codes?

Armatherm cladding attachment systems deliver a major boost to wall assembly efficiency. ArmaGirt™ Z Girts, clips, and thermal break shims combine low thermal conductivity with strong mechanical performance, allowing loads to be transferred while minimizing energy loss.

Armatherm resources

Downloads

Request a Quote

If you require a quotation and know the following product information, complete through form below.

The Problem with Metal Z-Girts

Steel Z-girts cut through exterior insulation, forming highly conductive paths that act as thermal bridges. These bridges lower effective R-values and can drop interior surface temperatures below the dewpoint, often leading to condensation, mould growth and long-term durability concerns.

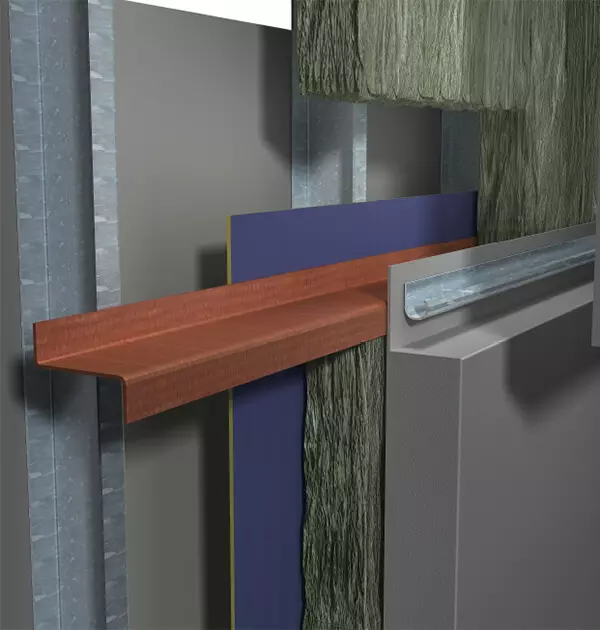

ArmaGirt™ fiberglass Z-Girts are pultruded from reinforced plastic, making them lightweight, non-conductive and robust. They replace traditional metal girts and brackets, maintaining continuous insulation and producing wall assemblies that are up to 98% efficient.

Product Advantages

- Manufactured in 7 standard depths: 1.5”, 2”, 2.5”, 3”, 3.5”, 4”, 6”

- High load capacity for a wide variety of cladding and insulation setups

- Non-conductive fiberglass composition

- Complies with ASHRAE 90.1 and NECB energy codes

- Easy installation with a dependable cladding anchoring surface

- Proven track record in numerous high-profile projects

Resources & Technical Support

Customers value ArmaGirt™ Z-Girts for their consistency, strength and quick delivery. Our website features case studies and testimonials from projects where fiberglass Z-Girts significantly improved energy efficiency.

We also provide an extensive library of technical resources including CAD/BIM details, test reports, installation guidance, literature and product profile videos. Our specialists are available to assist architects, engineers and specifiers in selecting the right solution to reduce energy loss and meet building regulation requirements.