What Is a Masonry Shelf Angle and Why Is It Important?

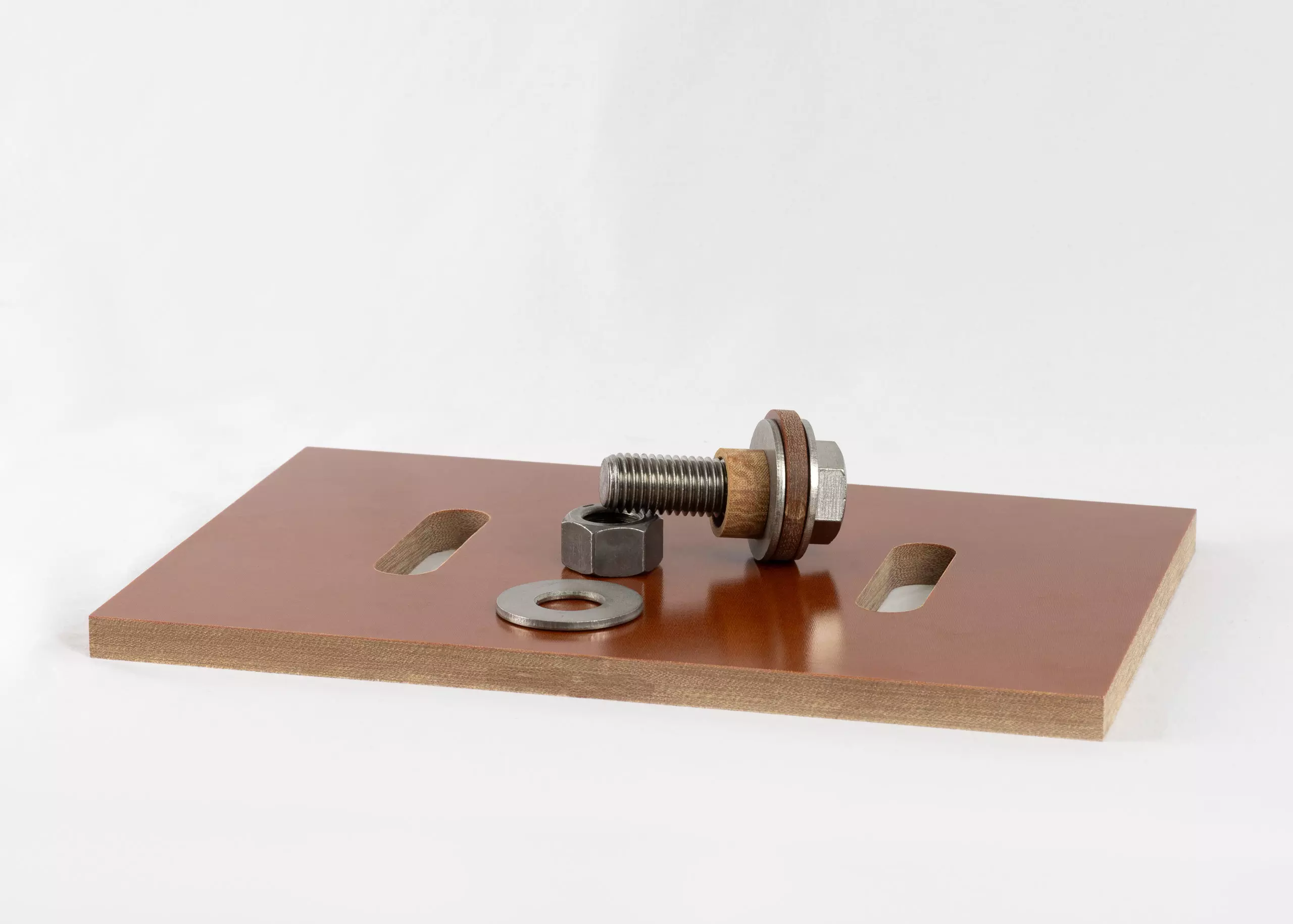

In the construction of multi-storey buildings, a fundamental detail that must be installed to protect the longevity of the structure is the masonry shelf angle. These steel supports take the weight of the brick or masonry veneer, transferring the load back to the structural steel or concrete framework through bolt connections. Without these in place, the masonry would be unsupported and at risk of cracking or buckling under its own weight.

Partnering with Armatherm™ for Long-Lasting Thermal Performance

At Armatherm™, we believe in transparency. We work directly with architects and developers to specify the right material for your project – not to oversell unnecessary products. To learn more about how Armatherm™ FRR can support your masonry relief system, contact us at [email protected] or +1 844-360-1036.