Using Armatherm in Cast-In-Situ Thermal Break Installations

The Role of Cast-In Situ Thermal Breaks in Modern Construction

When it comes to reducing heat loss in structural elements like balconies, slabs, and foundations, there’s one innovation that’s quietly transforming the way we build – it’s integrated, not appended.

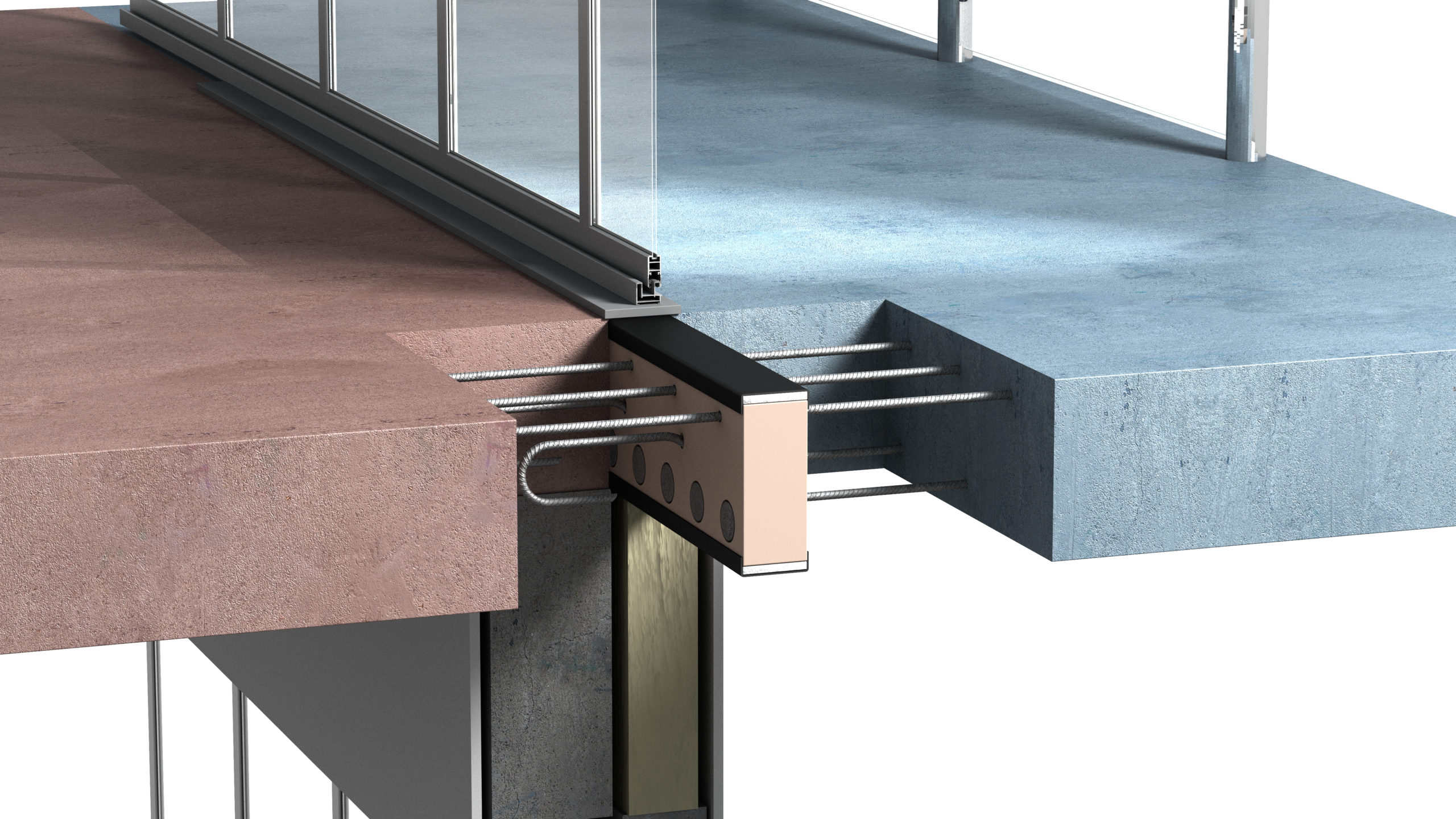

Armatherm’s Cast-In Situ thermal break solution is designed to integrate seamlessly into concrete pours, delivering exceptional thermal performance right at the point where it’s needed most. Whether you’re tackling a balcony junction or a heavily loaded structural connection, our Cast-in Situ thermal break can have a huge impact on a building’s energy efficiency.

What is cast-in situ?

Unlike traditional thermal break materials, the cast-in situ product integrates within flooring foundations where cement is poured directly on top, hardening in place to form a thermal barrier between internal and external elements. This method ensures a perfect fit every time – no gaps, no misalignments, just working towards continuous insulation.

Why Addressing Thermal Bridging Is Critical for Energy Efficiency

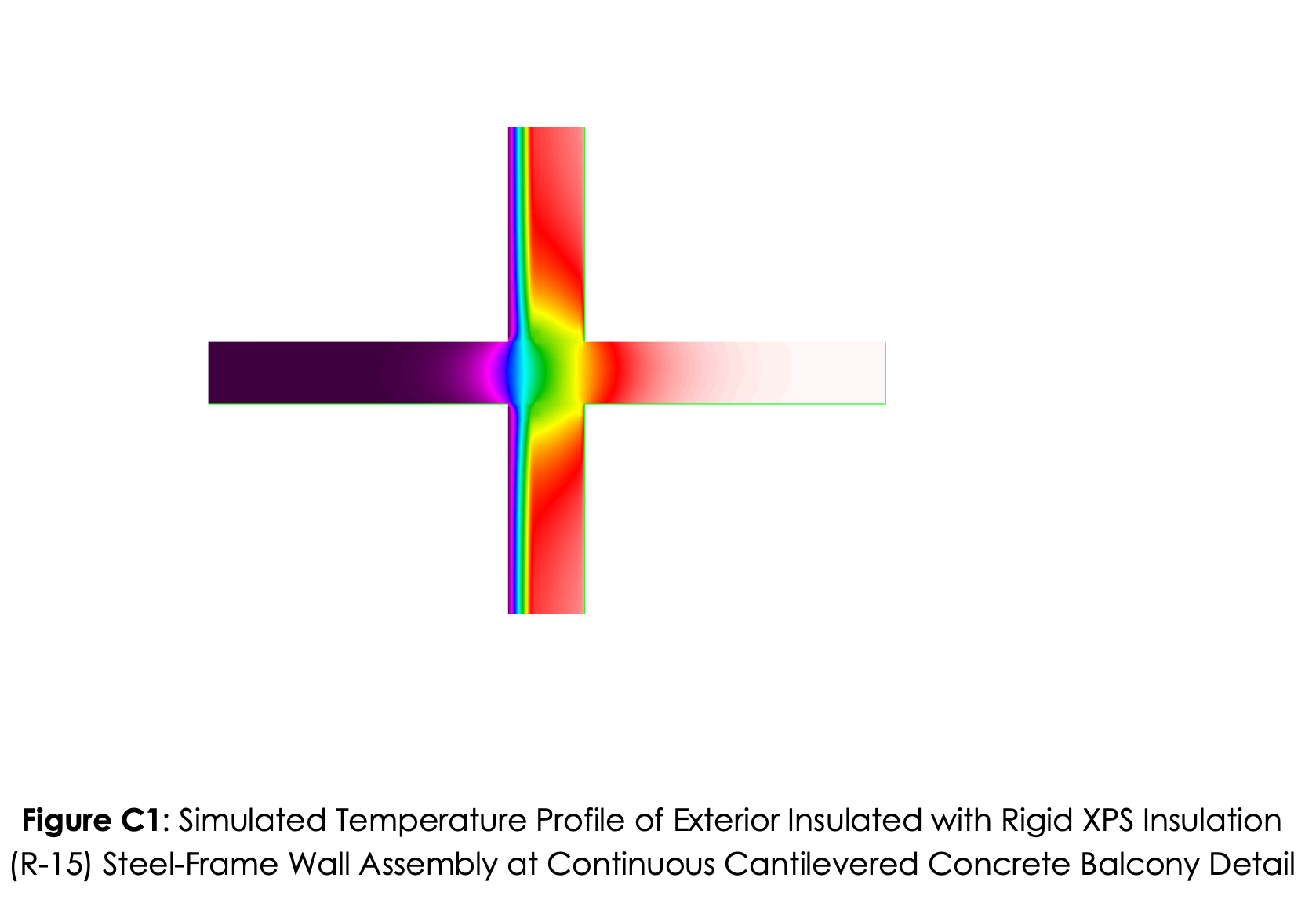

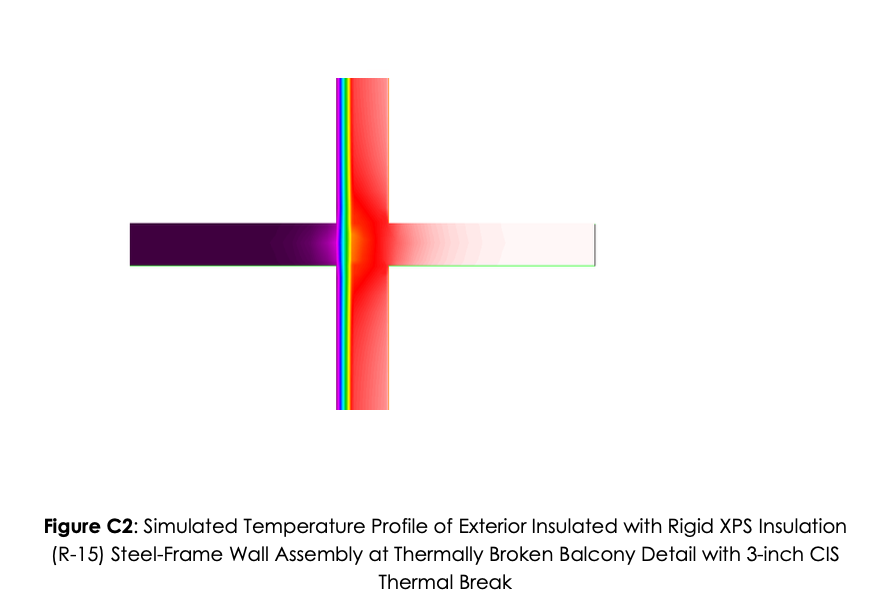

Thermal bridging is a significant issue in the construction industry and is one of the biggest contributors to heat loss (up to 30%) in modern buildings. At points where structural elements cut through insulation layers such as balconies, parapets or canopy connections, heat is able to transfer easily which ultimately creates cold spots, leading to condensation risks, and higher heating bills.

Because of this, it is essential to address the issues with thermal bridging in order to ensure energy efficiency and optimal thermal performance – that’s where the Cast-in Situ product from Armatherm can help.

Why choose Armatherm Cast-in Situ thermal breaks?

Installing an Armatherm Cast-in Situ thermal break will combat issues with thermal bridging and because of its innovative design it means that it can be positioned in a time-efficient manner which ultimately makes it more cost-effective as well. In addition to this, our cast-in situ thermal break is also available with fire protection depending on the project.

Want to talk to our team about whether Cast-In Situ is the right fit for your project?

Drop us a message or take a look at our technical datasheets to explore the performance for yourself.

Other Articles

& Projects

The Cove: ArmaGirt Thermal Breaks Support Pursuit of LEED Points

Thermal Break Solutions in Brick Shelf Angle Support Systems

Thermal Breaking in Cladding and Modern Construction: Key to Energy Efficiency and Cost Savings

Sustainable Living Innovations – 303 Battery, Seattle WA

Insulation Solution for ALDI’s £25M Facility

University of Illinois- Townsend Hall

Armatherm thermal breaks supplied for the expansion project of Hampden Academy in Northern Maine-Case Study

Armatherm Structural Thermal Breaks used to create sustainable, luxury apartments in New York

Enhancing Energy Efficiency: Framingham State University’s Sustainable Ballroom Expansion with Armatherm