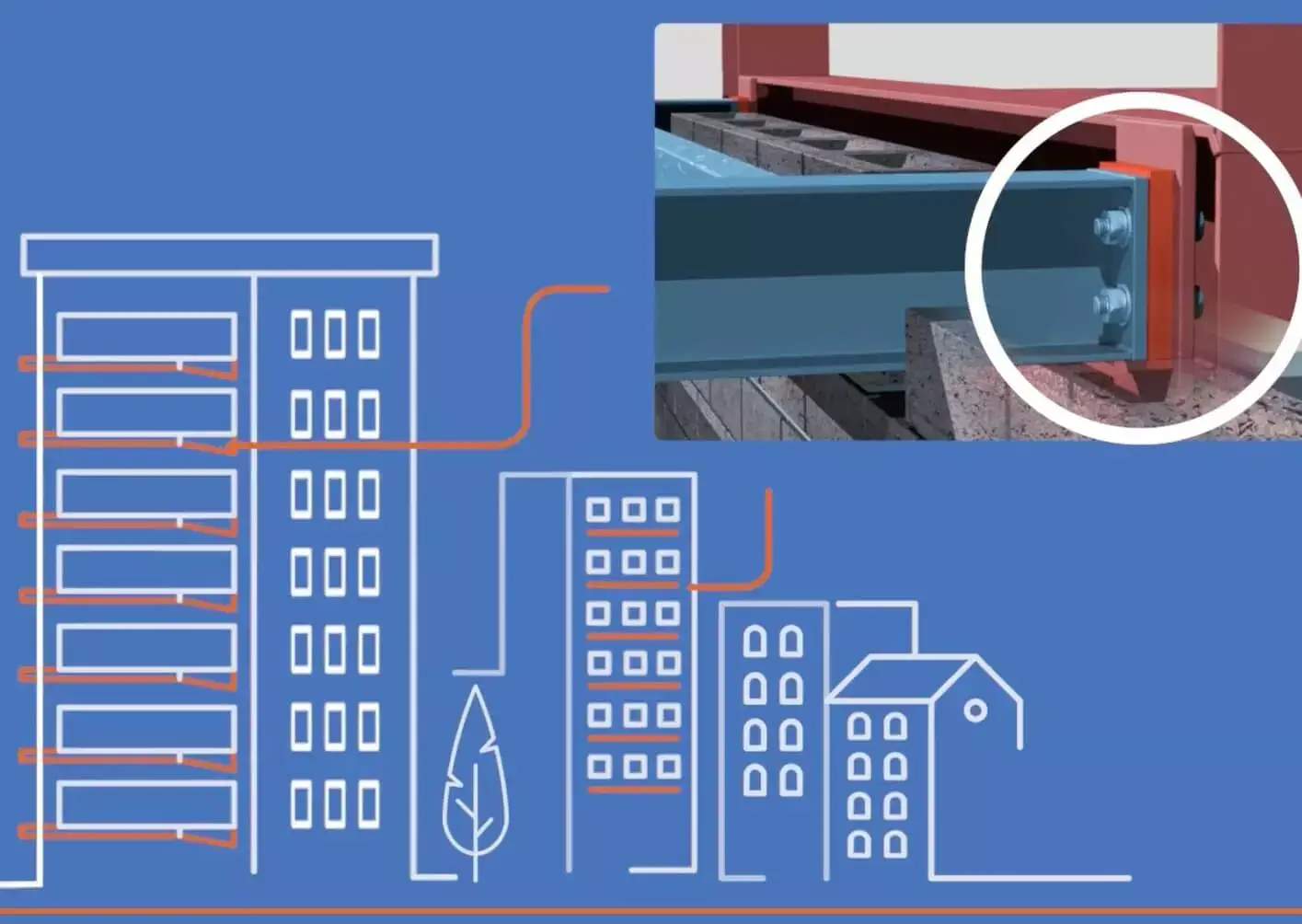

In construction today we have to look for every possible opportunity to improve the efficiency of the building envelope. Sorting and prioritizing areas where we can improve is a great place to start.

A key challenge that is often encountered in building construction is thermal bridging, also known as cold bridging, which can undermine the efficiency of a building’s insulation and significantly increase energy consumption. Thermal bridging results in heat transfer across insulation, creating areas of increased heat loss and in some cases, condensation and damp issues.

Traditional steel Z girts, often used to support cladding and insulation, are notorious for their heat-conductive nature, creating thermal bridges that compromise and short circuit the overall energy efficiency of a building envelope. Studies have shown that these steel attachments can reduce energy efficiency by up to 50%, allowing a significant amount of energy to escape. It’s ironic that the steel z girt, acting as the insulation retainer, turns out to be a big part of the problem!

By replacing steel Z Girts with Armatherm’s innovative alternative, contractors can achieve remarkable energy savings, improve overall energy performance and comply with building energy code standards. Wall assemblies using ArmaGirt™ Z Girt meets the continuous insulation requirements of ASHRAE 90.1 and Canadian NECB energy code.

The Armatherm product range includes a Z Girt, clip and thermally broken shims that provide a combination of low conductivity and high mechanical properties that transfer loads and reduce energy loss.

Armatherm’s innovative Z Girt products benefit from a simple installation process and secure cladding anchoring base. The cladding attachment systems significantly improve thermal performance. Armatherm’s FRP Z Girts install just like the steel girt, with self tapping screws, straight 9’ lengths go up fast, so no extra training is needed. Armatherm stocks 7 sizes ready to ship – 1.5”, 2”, 2.5”, 3” 3.5”, 4, and 6”.

It’s time to rethink traditional construction methods and embrace the future of energy efficient building envelopes. ArmaGirt™ Z Girt is in stock, in seven sizes – ready to ship directly to your site. Get in touch with us to arrange delivery today.